| Author |

Message |

| < 16ga. Ammunition & Reloading ~ GAEP Roll Crimping Tools |

|

Posted:

Mon Jan 30, 2012 9:16 pm Posted:

Mon Jan 30, 2012 9:16 pm

|

|

|

Member

Joined: 01 Dec 2005

Posts: 1550

Location: Minnesota and Florida

|

|

I purchased a GAEP roll-crimper in 24 gauge last year and I promised to post some pictures. I'm finally getting around to it. I have used Lyman roll crimpers for decades, in 20, 12 and 10 gauge - the kind you chuck in a hand drill. I have and use a "single pin" 28 from BPI, which I don't recommend, and a 16 I got through Precision Reloading that works pretty well. Of course Lyman's aren't made anymore - you're lucky to find one. Reloading tools for the 24 gauge are rare, and the only real hull choice seems to be 65 mm Fiocchi's from BPI. Gualandi wads are available also, but they seem dedicated to pretty wimpy loads of less than 3/4 oz. I doctored up a MEC 600 for 24 gauge a few years back, using 20 and 28 gauge parts, and some machine work. I was able to make a reamer to expand a 28 gauge black plastic final crimp die out to 24 gauge. Its a bit more difficult than you'd think, and I'm not sure it's worth it, as the star crimp takes up so much hull length. A roll crimp would make better use of that 65mm hull, and be easier than making the star crimps on little hulls with no crimp memory -- more on that later. It is a bear to find a good 24 gauge roll crimper, and usually they are some kind of antique. Once I became aware of GAEP in Italy, I was gratified to find they make a 24 ga. roll crimper. Working with the fellow from GAEP was really pleasant, and the roll crimper works quite well. I think his crimp tools are the best available right now. Here's a batch of 24 gauge. These are loaded with the Spred-R insert. The 20/28 gauge insert fits well in the 24. I roll crimp right down on it, and it forms the overshot wad. You know you've got a spreader load when you see that wad. Here's a photo:

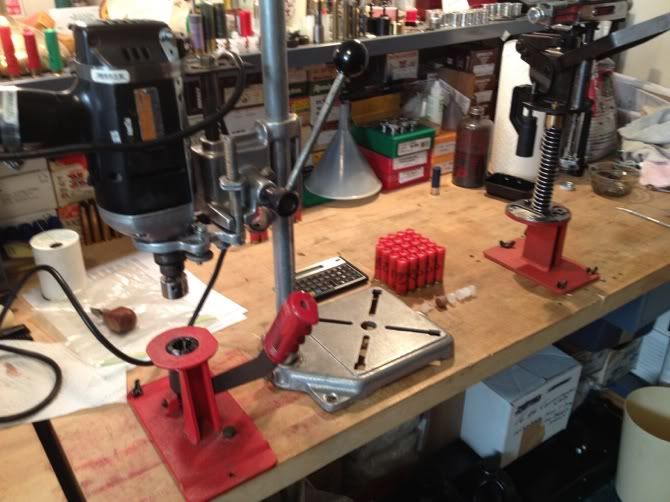

Here's my loading set-up. I use a MEC Super-Sizer to firmly and precisely hold the shell. I use a 28 gauge collet and back it out a bit so it only closes to 24 gauge diameter -- works great. The ring resizer I made for my MEC 600 works OK, but the little thin Fiocchi low-base brass heads like collet resizing a bit more. I have a very simple old benchtop drill press I align directly over the Super-Sizer. Its the old kind that holds a hand drill. It's pretty easy to line up over the shell. Once you load up a batch of shells, the roll crimping goes fast. Photo:

Here's a picture of my wad column components. On the right is a 24 gauge Gualandi reversible brush wad, available from BPI. Great wad, as it has a gas seal on each end! It's too long to use for my 7/8 ounce loads (16.5 grains Longshot, Fio 616 primer), but I like the gas seal. I cut them off with a utility knife -- you can see the result left of the full-length wad column. Then I use sufficient fibre filler wads (Circle Fly makes a lot of 24 gauge stuff and muzzle loaders use them in their .58 cal guns - same size). For the spreader loads I don't use a shot cup, but if you think you need one, you can always cut one from a Gualandi 24 gauge shot cup column -- BPI sells those too. On the farthest left, of course is the Spred-R insert:

Once again, I strongly recommend GAEP's products. I would think the 12 and 16 gauge roll crimpers would be the best you can get. Here are some more pics of the 24's -- the ones with the yellow top wad are Fiocchi factory loads for comparison:

Cheers! |

Last edited by MaximumSmoke on Tue Jan 31, 2012 5:47 am; edited 1 time in total |

|

|

|

|

|

|

Posted:

Mon Jan 30, 2012 9:18 pm Posted:

Mon Jan 30, 2012 9:18 pm

|

|

|

Member

Joined: 15 Apr 2007

Posts: 9464

Location: Amarillo, Texas

|

|

WOW

Those are first rate

I usually star crimp the 24 and 32 that we load

Mike |

|

|

|

|

|

|

|

Posted:

Mon Jan 30, 2012 10:02 pm Posted:

Mon Jan 30, 2012 10:02 pm

|

|

|

Member

Joined: 08 Nov 2005

Posts: 3438

Location: Illinois

|

|

VERY NICE--- great post  |

|

|

|

|

|

|

|

Posted:

Mon Jan 30, 2012 10:23 pm Posted:

Mon Jan 30, 2012 10:23 pm

|

|

|

Joined: 10 Feb 2011

Posts: 217

Location: Pacific Northwest

|

|

| Great post. It's good to hear that the GAEP roll crimpers work so well. However, I have to ask what kind of high power calculating is involved to require an HP15c at the bench? I recognized it from the bottom corner in your first pic. |

_________________

Matt

Nothing makes a gun more effective than practice. |

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 5:44 am Posted:

Tue Jan 31, 2012 5:44 am

|

|

|

Member

Joined: 01 Dec 2005

Posts: 1550

Location: Minnesota and Florida

|

|

Well naturally, there just is no shotgunning without an HP15c! How can you guys possibly shoot without calculations on recoil, square loads and leads with different muzzle velocities!   |

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 6:30 am Posted:

Tue Jan 31, 2012 6:30 am

|

|

|

Member

Joined: 08 Aug 2011

Posts: 1946

Location: Central CT

|

|

| Quote: |

| Well naturally, there just is no shotgunning without an HP15c! How can you guys possibly shoot without calculations on recoil, square loads and leads with different muzzle velocities.

|

You forgot chamber pressure and pheasant loads!!

Good to have you posting again.........I think!!  |

_________________

Mark |

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 7:23 am Posted:

Tue Jan 31, 2012 7:23 am

|

|

|

Member

Joined: 04 Mar 2008

Posts: 1943

Location: Lowcountry Ga.

|

|

| Remind us again how you were able to order the crimper. Seems I recall there was some sort of snag ordering them from abroad. Gil |

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 8:33 am Posted:

Tue Jan 31, 2012 8:33 am

|

|

|

Member

Joined: 01 Jul 2005

Posts: 640

Location: Crow River Bottomlands of Minnesota

|

|

Just to follow on Gil S post. Where did you order the tools from?

I just spent two weeks dealing with SIARM in Italy about their roll crimpers. We exchanged about 10 e mails trying to determine how to get a couple of their roll crimpers.

The staff person I was in conversation with used halting English, so I began e-mailing in Italian. After all the chit chat was done, me in Italian and she in bad English, the final e mail said (in Italian) "we are sorry, but we do not sell in the US or Canada. We are trying to set up a distribution program".

There is a SIARM roll crimper listed on Ebay by a seller in Australia for $124.00 plus $25 shipping.

So, once again, how did you order the GAEP crimpers and what was the cost. |

_________________

E.J. Churchill Hercules Grade 16

W.W. Greener Crown Grade 12

Stevens 311E 16

Browning Double Auto Twelvette

Browning Double Auto Twentyweight

Remington 1100 12 2 barrels

Charles Daly SxS 28 |

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 11:48 am Posted:

Tue Jan 31, 2012 11:48 am

|

|

|

Member

Joined: 01 Dec 2005

Posts: 1550

Location: Minnesota and Florida

|

|

I ordered directly from GAEP in Italy: http://www.gaep.net/

Here is their e-mail adress: gaep61@gmail.com

No doubt you will communicate with Charles -- the owner, I guess, and a very pleasant guy. He cares about the results you get. There are translation and keyboard character issues with the e-mails, but you can figure it out.

I don't know where prices are now, but I bought in July 2011, and paid $50 for a hardened steel crimper (lasts for at least 2.5 million crimps). A brass crimper (lasts for at least 1 million crimps) was available for $30. Shipping cost me $30, and the product arrived inexactly 2 weeks. I paid by PayPal.

It seems GAEP makes these parts for major cartridge manufacturers. No one would make a device that lasts for 2.5 million crimps and sell that as a feature to a handloader. You will notice from the site there are about a dozen different tools for the 12 gauge, but you only need one of them. There are subtle crimp depth differences, it seems. Pick the number 2, 3 or 4, and you'll probably never go wrong. They do not seem to supply such wide variation in the other gauges. Charles is trying to tap into the handloader market, which is much less sophisticated than the manufacturers. The brass version is not as wear resistant, but would be great for the handloader. It is less costly to produce, so price is lower. I'll probably try a brass one in 16 gauge. $30 is pretty inexpensive for such a tool.

Maybe this site should collect all their desires and send out a mass order, distributing the shipment costs over more parts to reduce the net price.

Cheers! |

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 11:51 am Posted:

Tue Jan 31, 2012 11:51 am

|

|

|

Member

Joined: 01 Dec 2005

Posts: 1550

Location: Minnesota and Florida

|

|

| Doggai -- I live in Minneapolis, by the way. |

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 12:26 pm Posted:

Tue Jan 31, 2012 12:26 pm

|

|

|

Member

Joined: 01 Jul 2005

Posts: 640

Location: Crow River Bottomlands of Minnesota

|

|

| I looked at the website products page. It's a little confusing. How does the crimper head spin? Drill press or hand drill? They show no shaft on the crimper. And, they only show 12 and 10 gauge. Did I miss something? JF |

_________________

E.J. Churchill Hercules Grade 16

W.W. Greener Crown Grade 12

Stevens 311E 16

Browning Double Auto Twelvette

Browning Double Auto Twentyweight

Remington 1100 12 2 barrels

Charles Daly SxS 28 |

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 2:03 pm Posted:

Tue Jan 31, 2012 2:03 pm

|

|

|

Joined: 12 Sep 2010

Posts: 1973

Location: Maine

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 3:50 pm Posted:

Tue Jan 31, 2012 3:50 pm

|

|

|

Joined: 28 Mar 2008

Posts: 1460

Location: Eagle, Nebraska

|

|

I have a couple of those 24 heads. Work fine. Use the same longshot load for 7/8oz loads. Have not had them tested as My "tester" doesn't have a 24ga test barrel. No matter.

I have been wanting to have a Mec Jr "tweeked" so I could reload, my only need really is de priming and re-sizing. Can do the rest if need be. I have a line on that, just have not followed through with it yet.

SIARM difficult to deal with. But I had a connection in Rome at the time, and they purchased them for me. (cousin studying in Rome)

How do you re-size your brass???? |

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 4:30 pm Posted:

Tue Jan 31, 2012 4:30 pm

|

|

|

Member

Joined: 23 Dec 2008

Posts: 288

Location: Mississippi

|

|

I originally purchased a roll crimp toll from Precision Reloading and it works fine. Then I stumbled onto the GAEP tools and ordered one of those from Charles. Nice fella and excellent service. Think mine cost $65 thru Paypal. The GAEP works great. But then I found a new Lyman tool so I bought it also.

Here are the differences I've found between the tools. If you are trimming 2 3/4 fold crimped hulls to 2 1/2 or rolling fold crimped 2 1/2s the Precision tool does a much better job...in my experience. The Lyman/GAEP will work but the roll crimps are not perfectly round on the inside...have squared inside corners...but still shoot fine...just don't look nice. The GAEP/Lyman give great looking crimps on non-crimped hulls as does the Precision toll but the Precision crimps are not as full bodied or rounded as the GAEP/Lyman. They tend to be sharper/flatter at the crimp end.

Maybe this makes sense as it is sorta hard to describe. Here's a couple of photos I have of my GAEP tool. The threaded piece screws into the tool body and then chucked in your press or drill.

Hope this helps.

Mike

|

|

|

|

|

|

|

|

Posted:

Tue Jan 31, 2012 4:41 pm Posted:

Tue Jan 31, 2012 4:41 pm

|

|

|

Member

Joined: 01 Dec 2005

Posts: 1550

Location: Minnesota and Florida

|

|

First Doggai's question -- the crimper is intended to attach to a motor with a threaded stud, and the spanner holes allow it to be drawn up tight to a shoulder on the drive shaft. This attachment method is used on the commercial reloading machines, evidently. Charles supplies a little piece of metric 6mm threaded rod to screw into the hole and chuck in a hand drill. I didn't like that, so I simply got a nice standard 50 mm long 6mm dia. x 1mm pitch screw (bolt or socket head capscrew - get it at your hardware store or Home Depot, etc), checked it for thread depth, and then cut off enough thread so the un-threaded shank of the capscrew butted up against the edge of the threaded hole in the crimper when fully screwed in. Tighten it up real good, and then cut off the head of the bolt/capscrew. File a nice chamfer on the cut end. The result is a nice smooth almost 1/4 inch shaft you can chuck in your hand drill. It came out straight and concentric. Looks nice - works nice.

Now for Hootch! -- As I mentioned before, I can use either of two methods to re-size my 24 gauge brass. If all you need to do is re-prime on a MEC Jr, by the way, just use a 28 gauge loader or re-prime plunger as is. Same with powder and shot drops and wad insertions -- use the 28 gauge tools -- just make sure to bore out the shell base holder with your Dremel tool, or just take it off!

If you want to re-size on the MEC Jr, you need to bore out a 28 gauge re-size ring. That is re-size method number one. I simply chucked a 28 gauge re-size ring into a lathe (square and concentric!) and bored it out. You need to get it to about 0.650 to 0.655 inch diameter. Do a smooth job and leave a little (not too big!) entrance radius just like the ring had before you bored it out. Here is a site on chamber dimensions for shotshells: http://www.dave-cushman.net/shot/shotshellloads.html You need to be smaller than the "B" dimension by about 0.005" or so.

Method number two uses the MEC SuperSizer. Just get a 28 gauge re-size collet, and leave it threaded out a little so it will not fully close. Got to first remove the lock nut under the base - use a good 6-point socket, a wrench wont fit -- nut is very thin! Be patient and screw the collet in a bit at a time to find the point where it is tight enough to re-size to the diameter mentioned above, then re-install the lock nut. Done. This method is better for the hull and better functioning in double guns, as the Fiocchi brass base is thin and short and the ring re-size method will sometimes result in a slight flair at the top of the brass. The resulting edge standing proud of the hull wall will catch sometimes on the extractor recesses of double guns, causing the brass to buckle and wrinkle, often locking the shell into the chamber and ruining the hull. The SuperSizer method avoids that.

Load On!! |

|

|

|

|

|

|

|